Best Fabrics for Digital Fabric Printing: A Surface Designer’s Guide

- Jo Phillips

- Aug 20, 2025

- 3 min read

Research, Insights & A Book Worth Bookmarking

I’ve been doing a lot of research lately, The Complete Guide to Designing and Printing Fabric by Laurie Wisbrun has been glued to my side. It’s full of technical detail, but here’s what stood out to me as a surface pattern designer focused on digital printing.

Some of this won’t be new to those already deep into surface pattern design. But for anyone starting out, or considering fabric printing for the first time, here are the most useful lessons I’ve learnt so far.

Understanding Fabric Types for Digital Printing

One of the first things that stood out was how fabric type affects everything. Laurie Wisbrun breaks it down into three main categories:

Cellulose fibres

Cotton, linen, hemp. These are plant-based and take colour well.

Protein fibres

Silk and wool. These come from animals and behave differently when dyed or printed.

Synthetics

Polyester, rayon, nylon. These can be tricky to dye and aren’t always ideal for digital pigment printing.

For me, that’s a useful reminder to think beyond aesthetics. The fabric’s composition matters when it comes to colour, texture, and durability, especially when printing digitally.

How Fabric Treatment Affects Print Results

Terms like PFD (Prepared for Dyeing) and greige goods (untreated natural fabrics) kept popping up. Fabrics that have been bleached or optically whitened with softeners may not print as well with pigment inks, so knowing how your fabric has been pre-treated is important.

Top tip:

The cleaner and less treated the fabric, the better the result.

Pigment vs Dye Printing: 3 Key Takeaways

As a surface pattern designer, this section really made me pause and reflect. Here’s what stood out:

1. Pigment printing is eco-friendlier, but more delicate

Pigment inks sit on the surface of the fabric. They’re more environmentally friendly, require fewer chemicals, and don’t need pre-treatment - which makes them great for low-impact production.

However, they can be prone to fading or rubbing off if the fabric isn’t handled or washed with care.

2. Dye printing gives richer results, but comes at a cost

Dye-based printing chemically bonds with the fibres, producing bolder, deeper colours. The results are often stunning - but it’s a more complex, expensive process that uses more water and chemicals.

3. Collaboration helps me design with intention

While the final print method is usually chosen by the manufacturer, I can guide the design process. By discussing fabric type and print process early in the brief, I’m able to tailor colour palettes that perform beautifully - whatever method they choose.

The Freedom of Modern Digital Fabric Printing

I love how accessible fabric printing has become. Thanks to companies like Spoonflower and others, you don’t need to order thousands of metres or commit to giant print runs. You can:

Order a swatch or a fat quarter

Test things before investing more

Explore without the pressure of minimums

Just remember: it’s worth remembering that not all colours print exactly as they appear on screen, especially neon, deep blacks, or out-of-gamut shades.

Always Order a Swatch

This is the one rule I’ll never skip again. Every fabric, printer, and colour behaves a little differently. A test swatch helps you avoid costly surprises and gives you confidence in your final product. Seeing the real thing in your hands is the only way to be sure it matches your vision.

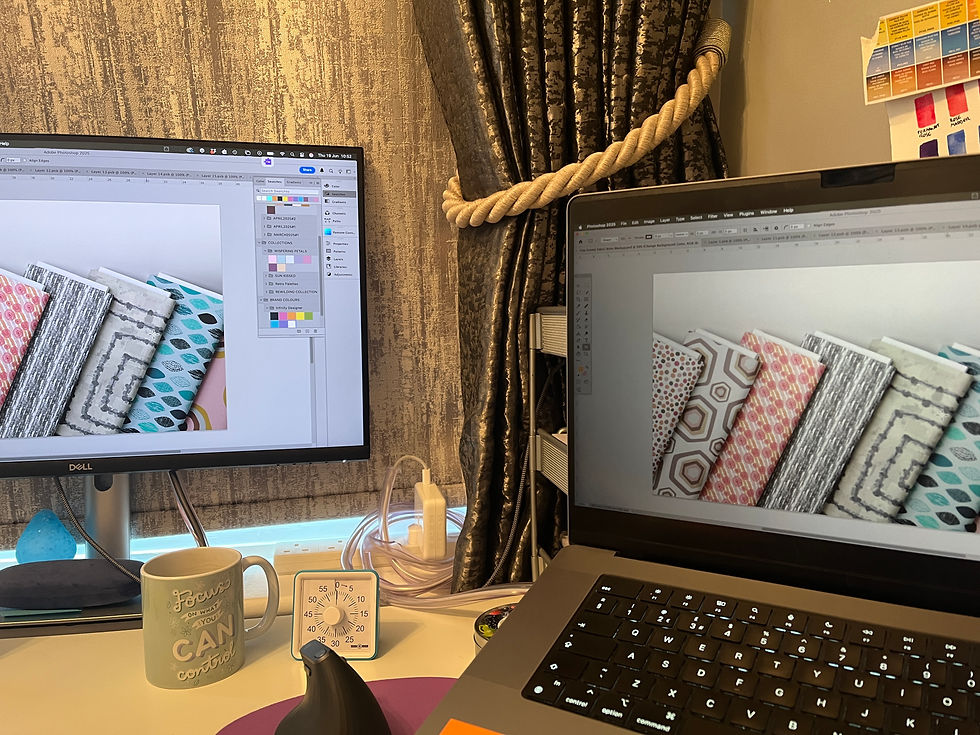

Final Thoughts from the Studio

This book’s a treasure trove for anyone working with fabric design. This book deepened my understanding of digital fabric printing, even though not everything was directly relevant to my licensing work. It’s a great reference if you’re starting out or scaling up.

I’ll be keeping these tips in mind as I continue to develop my own designs and collections - and if you’re thinking about printing your own fabric, hopefully this helps you feel a little more confident in where to start.

Work With Me

If you’re a brand, buyer, or art director looking for licensing-ready designs that are created with materials and production in mind, I’d love to connect.

Get in touch for custom collaborations or explore my current collections.

Comments